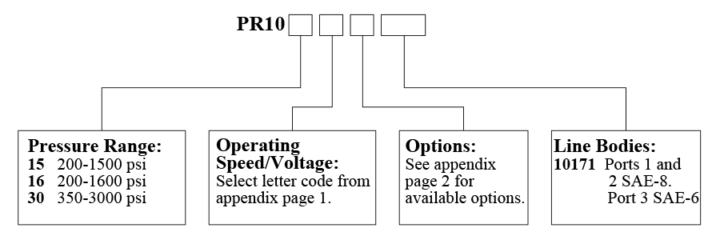

Function

- Motor driven, Cartridge-style, Hydraulic pressure reducing/relieving valve with internal spring chamber drain, designed to act as a pressure-regulating device for secondary circuits.

Operation

- The PR10 allows flow to pass bidirectionally from 2-1 with the spring chamber constantly drained at 3.

- Once pressure reaches a pre-determined pressure at port 1, the cartridge shifts to restrict input flow at 2, thereby regulating pressure at 1. In this mode the valve will also relieve 1 to 3

Operating Pressure

- 3000 psi maximum

- 500 psi maximum on drain line (port 3)

Pressure Ranges

- 15 200 to 1500 psi

- 16 200 to 1600 psi

- 30 350 to 3000 psi

- Custom ranges are available upon request

Voltage

- 12 & 24 VDC

Construction

- Cage, body and spool: Steel, exposed parts plated

- Motor housing assembly: Anodized aluminum

- Standard line bodies are aluminum

- Steel bodies are available upon request

Seal Material

- Buna N and polyurethane standard

- Viton optional

Current Draw

(Only while adjusting)

- 0.8 amp when powered at 12 volts

- 1.0 amp when powered at 24 volts

Temperature

- -40 to 120°C