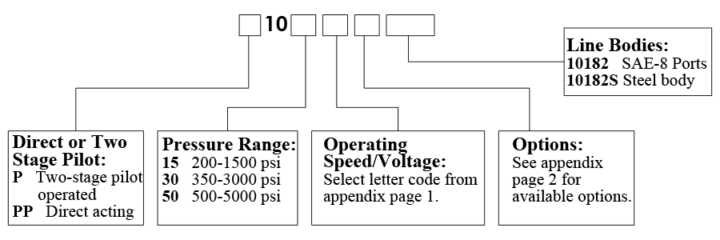

Function

- Motor driven, Cartridge-style, hydraulic relief valve. Intended to be used as a remote control of hydraulic system pressure.

Operation

- Block flow from 1 to 2 until sufficient pressure at 1 to force the relief off its seat.

- P10 two stage pilot operated 15 gpm

- PP10 direct acting 1 gpm

Operating Pressure

- 5000 psi maximum

Pressure Ranges

- 15 200 to 1500 psi

- 30 350 to 3000 psi

- 50 500 to 5000 psi

- Custom ranges are available upon request

Voltage

- 12 & 24 VDC

Construction

- Cage, body and spool: Steel, exposed parts plated

- Motor housing assembly: Anodized aluminum

- Standard line bodies are aluminum

- Steel bodies are available upon request

Seal Material

- Buna N and polyurethane standard

- Viton optional

Current Draw

(Only while adjusting)

- 0.8 amp when powered at 12 volts

- 1.0 amp when powered at 24 volts

Temperature

- -40 to 120°C